8 October 2013

Glastonbury demonstrates there's a market for specialist print products, which require specialist skills

During June the BPIF advertised for a Linotype Operator and a Heidelberg Cylinder Press Operator – volunteers came forward and this is the facilitating story, by Ian Fairhurst, of how the Glastonbury Print Team produced a free paper at the Festival.

But what is also very interesting, is that, although Glastonbury showcased some wonderful hand crafted print, there does seem to be a revival or even renewed interest in specialist printing. One specific example would be high quality stationery for the exploding wedding market space and no doubt other similar examples exist.

This story is not only about the Glastonbury Free Paper, but traditional print, traditional skills and print restoration. The BPIF has a special interest group called BESA which focuses on this very specialist sector of our Industry. Please take a look at and enjoy the story of Glastonbury.

www.britishprint.com/page.asp?node=163&sec=BPIF_Engraved_Stationery

1960 Harris Intertype linecaster, ready for action at Glastonbury

Glastonbury Free Press – 2013

It was a simple enough remit, to print 15,000 newspapers by letterpress in time for breakfast on each of the three days of the festival.

So there we were, a classic 1947 Heidelberg cylinder press, 1960 Harris Intertype linecaster complete with ½ tonne of type metal, a beautifully restored vintage hand fed folding machine, 100,000 sheets of newsprint and a dozen willing hands, sleeves rolled up ready to rock and roll.

But as with all the best laid plans …

In the weeks leading up to the festival a concrete raft complete with date stamp had been laid in place in the middle of what would become the Circus and Theatre field at the festival. With hindsight probably the best place for us as the circus and theatre of producing the Glastonbury Free Press unfolded.

The machinery had been delivered, power, including three phase, laid on and with the addition of a marquee to keep out the weather and decking to keep out the mud a printing office was in place. What could go wrong!

60,000 red top mastheads had been produced the week before so we knew the press was working fine, at a top speed of 3,000 iph 20 hours to produce the red tops meant a further 10 hours for each edition of the paper.

Our press operator volunteers had been split up into shifts, ready to run the press through the night to meet the deadline.

Then disaster struck. Time to power up the Intertype Wednesday morning and the motor self destructed. Inspection by the on site electrician confirmed our worst fears that a new motor would be required. With no real clue as to when this would happen or whether it would solve the problem the prospect of not printing any newspapers was beginning to loom large.

Interest in the project had begun to spread throughout the whole festival with people coming to enquire about the paper, radio and TV people were wanting to arrange pieces for various high profile shows and we had nothing to show. Articles for the newspaper had been prepared and the plan was to also sell small ads for inclusion and also use space for late changes to the various line-ups, it wasn’t looking good.

Besides producing the newspaper the other part of the project was to have demonstrations of letterpress printing. Our comps had already begun producing posters on the four proofing presses we had and allowing people to print their own was proving popular. To keep up with demand we could at least have the press running by printing some of the posters on the Heidelberg. This also turned out to be a good move. There was a constant stream of visitors wanting to view the machinery and the posters were disappearing as fast as they could be printed. At least something was going right.

Friday morning arrived, the first official day of the festival, after heavy rain the previous day and still no signs of a paper being produced morale was at rock bottom. We needed a plan.

Fortunately some of our volunteers still work in the commercial sector and between them a plan was beginning to take shape. The original idea to produce three editions went out the window but with access to the right equipment some willing local contacts, a bit of luck and some hard work a single edition could be produced for the morning of the last day.

The press office found us a Mac laptop, no mouse just the trackpad, but hey you can’t have everything but it did have a working copy of InDesign installed.

A local company was put on standby to produce a set of plastic plates to print off. It was lunchtime Friday, at last we were up and running with the real prospect of having a newspaper out for breakfast Sunday.

Just as well, by this time the new motor for the Intertype had arrived, been wired up but to no avail. On powering up, the starter box blew. It was now apparent that two weeks, albeit undercover, in the middle of a field had not done the electrics of this vintage piece of kit any good and the damp did for it in the end.

In four hours on Friday afternoon the four pages of Sunday morning’s newspaper were put together. With a now limited edition, some high profile authors had their articles canned, but the few small ads that had been sold were included, along with a strip cartoon, a lead article about the quality of the Rolling Stones performance on Saturday evening (fingers crossed that it would be) and it was beginning to look good. The pages were PDF’d and emailed to the platemakers.

Saturday morning the plates had arrived, it was now down to the press operators. It had been going too well, the plates were mounted up on the base only for it to be discovered that the base was 3mm shallow of type high. 3mm is a lot of make ready! Time for a conference. The solution lay just outside the printing office. Nobody knows where it came from but a discarded door with plywood panels had been lying around by the back of our marquee. The panels happened to be 3mm ply plus paint, it might just work. Out came the joinery tools.

It took from 8-00 am till 5-30 pm Saturday to make the first side ready. It could have been made this easier by ordering deep etch plates, as the inking rollers on the press proved to be somewhat out of true, fine for wooden poster type but a bit of a nightmare with our shallow etched plates. The guys on the press persevered with a magnificent effort making the job ready.

By 5-30 the press began to roll with ten hours to run it was looking like the Glastonbury Free Press Edition 1 would be joining the usual crop of Sunday papers.

Sunday morning arrived; the press had run all night. As a measure of the quality of this machine, apart from having to stop to reload, it had tripped out only half a dozen times. By 8-30 the last of 15,000 copies of the Glastonbury Free Press Edition 1 were being put through the folder. Transport had been arranged and the paper was soon being sent to various distribution points around the 900 acre Festival site. Word spread and what started as a trickle soon turned into a flood of people arriving at the office to collect their own copy. Within two hours all 15,000 had gone. Not to be disappointed people were happy to take away even the make-readies as a souvenir. There was a subsequent report that the paper had even been reviewed along with the other Sundays by John Humphries on his Sunday morning programme. All agreed that it had been a satisfactory end to what could have been a total disaster.

Lessons had been learned. Everyone on the team agreed that by taking these lessons on board and with some forward planning, next year will see Glastonbury Free Press Editions 2 – 4.

And the Rolling Stones didn’t disappoint.

Written by Ian Fairhurst who was part of the Glastonbury Press Team.

Intergraf Economic News (Paper Prices) - March 2024

Intergraf Economic News (Paper Prices) - March 2024

18 March 2024

Access the latest edition of the Economic Newsletter for the European Printing Industry for data on paper consumption, and pricing data for pulp, paper and recovered paper. Data for packaging papers and board is also available with this edition.

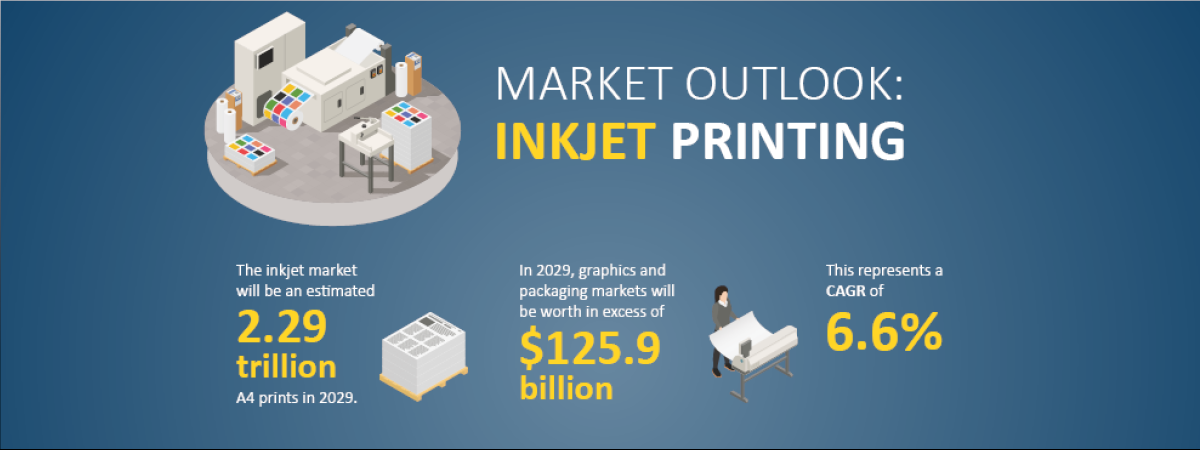

UK to follow global expansion of inkjet printing

UK to follow global expansion of inkjet printing

21 March 2024

The latest expert analysis from Smithers identifies the potential of the latest generation of inkjet systems to improve profitability across the global print market. Read more about the new report The Future of Inkjet Printing to 2029.

The BPIF is the printing industries champion. By becoming a member you join a diverse and influential community. We help you solve business problems, connect you to new customers and suppliers and make your voice heard in government.

Call 01676 526030