27 October 2015

Technology update for Park Communications

Park Communications has announced yet another major capital investment for 2015. The multi-award-winning, leading London print house is to further enhance its service with the installation of a 6-colour RAPIDA 106 press with integral coating and KBA's ground-breaking performance and quality-assurance technologies. The announcement follows purchases earlier this year of a 7800 HP Indigo digital press and Kalmar mailing equipment with mail matching software.

The new B1 RAPIDA is due to be commissioned at Park’s 4,275m2 Beckton site early in the New Year. Included in the specification are KBA’s unique SIS sidelay-free sheet infeed, SPC simultaneous platechanging, coater unit and the patented VariDry ‘slide-in, slide-out’ cassette-based drying system. QualiTronic Professional, the highest level of quality assurance, combines in-press colour measurement and control with image inspection and correction of every sheet at production speeds up to 18,000 sph. LogoTronic Professional is a comprehensive management system that interfaces with the host MIS for real-time transference of CIP3/CIP4 and JDF/JMF job set-up data and performance information.

The new press represents not just a change of manufacturer for Park Communications but also a change of configuration, since the straight KBA will be running alongside Heidelberg Speedmaster long-perfecting presses; Managing Director Alison Branch explains:

"The technology has advanced so much that the productivity of a sheet work press can match our older perfecting presses – this is especially the case as our runs are tending to shorten. Also jobs may often require four-colour process plus two specials then a seal or a coat, so we took the opportunity to create a configuration that would allow us to offer a wider range of options more efficiently… it will allow us to enhance the look and feel of high-end publications"

Five key benefits

Alison Branch identifies five ways in which the new press will enhance Park’s service to its customers, the first being the opportunities it introduces for product differentiation:

"One of our strengths is the way we are able to advise our clients on how they can add creativity to their marketing collateral. For example, print is now able to engage different senses in addition to the visual. Extra colour units and a coater will allow us to add more options to enable customers to differentiate their products with value-adding finishes that may be tactile or even scented."

The second is a matter of convenience: the faster makereadies and in-press quality systems don’t just aid productivity, they mean clients need spend less time out-of-office to pass their work on press.

Brand integrity is of ultimate priority to Park’s clients and the third benefit represents a defining factor in the decision in favour of the RAPIDA press. KBA’s in-press colour and content assurance regimes were chosen to provide the ultimate levels of confidence:

"When printing at 18,000 sheets per hour you could have printed hundreds of sheets before you spot a problem," continues Alison Branch. "QualiTronic Professional alerts the minder to the issue immediately so that he can correct it and make the decision as to whether or not it’s something that needs rejecting. That means total confidence in the quality of every printed sheet."

The fourth benefit stems from the RAPIDA’s superior production efficiency, which reduces turnround times and allows for more flexibility in scheduling work, while the fifth is the improvement in carbon footprint as the new technologies reduce waste and provide more effective use of energy inputs.

Team decision

The choice of press was made after a rigorous review of alternatives including full on-site testing over a wide range of substrates and technically challenging designs. It was particularly important to Park, too, that one of its No.1 pressroom operators was a member of the assessment team. Maintenance support, the quality and productivity of the RAPIDA 106 6 L, excellent customer service offered by KBA and overall value-for-money were all factors that contributed to the decision.

Alison Branch concludes: "We are delighted to be able to enhance our service to customers by offering the full suite of creative finishes, speed up press passing, be even more environmentally friendly and support our customers by taking on more projects. The KBA RAPIDA 106 6 L is a tremendously exciting press."

For KBA (UK) Ltd. Managing Director Andrew Pang says: "We are delighted that Park Communications has chosen KBA for its latest press investment and we are totally committed to doing everything we can to make this new business partnership a success. Together with other recent installations at sector-leading print operations, this decision demonstrates that KBA’s next generation RAPIDA presses have the technology and performance criteria to make a crucial difference in the delivery of superior products and services."

Intergraf Economic News (Paper Prices) - March 2024

Intergraf Economic News (Paper Prices) - March 2024

18 March 2024

Access the latest edition of the Economic Newsletter for the European Printing Industry for data on paper consumption, and pricing data for pulp, paper and recovered paper. Data for packaging papers and board is also available with this edition.

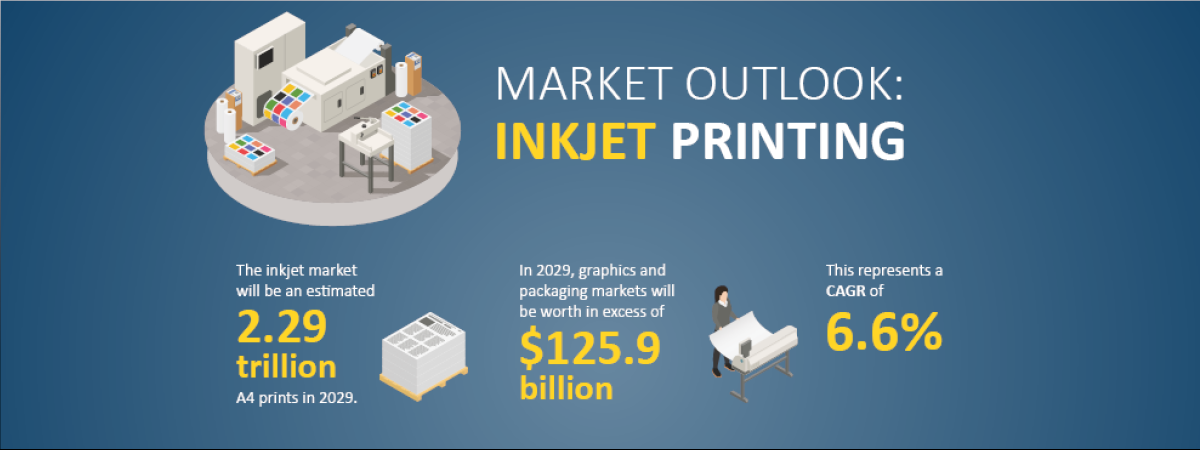

UK to follow global expansion of inkjet printing

UK to follow global expansion of inkjet printing

21 March 2024

The latest expert analysis from Smithers identifies the potential of the latest generation of inkjet systems to improve profitability across the global print market. Read more about the new report The Future of Inkjet Printing to 2029.

The BPIF is the printing industries champion. By becoming a member you join a diverse and influential community. We help you solve business problems, connect you to new customers and suppliers and make your voice heard in government.

Call 01676 526030