25 July 2006

BPIF puts Fogra & GRACoL G7 colour calibration methods to the test

Two different methods of implementing the ISO 12647-2 standard printing conditions came under the microscope at a UK colour testing day organised by the newly reformed BPIF Technical Standards Committee on Thursday 20 July at Heidelberg UK’s Brentford showroom. Led by Committee Chairman and White Horse Press Joint MD Peter Arnel, the purpose of the event was to conduct methodology and printing tests using both the Fogra and IDEA Alliance GRACoL G7 ä methods. This allowed delegates to appreciate how the two separate methods are applied and to assess colour quality and appearance by comparing the printed results together as produced by both systems.

In his introduction and welcome to the 50 people present, Peter Arnel expressed concerns over the variable colour standards found within the industry, and encouraged the general adoption of ISO 12647-2 by printers in order to address this. Also presenting on the day were Dan Wilson, the first European-based colour consultant to be accredited by IDEAlliance (developers of the GRACoL) to implement the GRACoL7 method, and Paul Sherfield of the Missing Horse Consultancy, who developed the test forms and co-ordinated the event.

All the printing tests were conducted on a Heidelberg Speedmaster CD 74 -10 colour press running with a specified colour sequence of black, magenta, cyan and yellow. A colour test form was designed and prepared to incorporate both the Fogra and GRACoL7 control bars. In addition, GRACoL7 also included a series of multi-tone grey scales. In addition, this test form contained five duplicate examples of halftone four-colour process images of demanding subjects, from the Altona visual test suite, separated to both Forga 27 and G7 for comparison and assessment purposes.

The first task of the Heidelberg print technician was to obtain the press fingerprint information from the test form by achieving the specified standard colour densities on the solid patches across the sheet, which were read and confirmed by the Heidelberg ImageControl traversing colour spectrophotometer.

Eric Koldenhof from Colorware in the Netherlands used his interesting ‘Pressview’ software to also validate the sheets to the Fogra 27 printing conditions, Paul Sherfield also checked the sheets manually using a Gretag Macbeth SpectroEye.

From this data it was possible using the Fogra colour control bars to calculate the amount of press dot gain in order that the Heidelberg pre-press technicians could produce new corrected plates. Analysing the recorded information it is possible to alter the initial colour curves i.e. calculating a dot gain allowance for all future four-colour halftone separations for that particular press.

The GRACoL7 method requires the detailed analysis and calibration of the multi-tone grey scales. From this data it is possible to plot two curves CMY and black to achieve a specified grey balance. From this data the colour curves can be adjusted, which are then sent to the RIP of the CtP device prior to output new colour corrected plates.

Both of these approaches require appropriate measuring equipment i.e. a colour spectrophotometer, which must be accurately calibrated in order to be able to measure the colour values correctly. The captured colour data is then used to adjust the setting of the curves within the CtP RIP so that an accurate representation of the original/proof can be printed.

Whilst this essential calibration work was in progress Dan Wilson presented the GRACoL7 approach to implementing ISO 12647-2. He explained that both Fogra and GRACoL7 used the same L a. b. colour space values although it was suggested in practice that some small correction to the existing L a. b. values could lead to a benefit for printers. However, as the GRACoL7 system used a series of multi-tone grey scales for calibration purposes and any variation away from the grey specification could be adjusted using the combined CMY and black curves. Making adjustments to the two curves was not directly linked to dot gain but in effect to achieve the corrected grey colour values the halftones would be changed.

Under the direction of Heidelberg colour management specialists Mikki Winn and Steve Fowler two further sets of plates were made following the initial calibration work. In turn both sets of plates with the Fogra ISO curve and the GRACoL7 were printed on the Heidelberg 74 CD press. When both sets of printed sheets were subject to close comparison the colour and appearance of the two tests results were remarkably close, which indicated whatever method favoured by printers to calibrate the press using either the conventional Fogra or the GRACoL7 approach both could achieve the ISO 12647-2 standard.

Finally a set of plates containing the five test images, separated to Fogra 27, (from both the ECI ICC profile and the Adobe Fogra 27 profile from CS2) a beta profile from GRACol G7 data, and a Beta profile from Fogra 39 data, were producted from both calibrations and printed.

Peter Arnel concludes “There was general agreement amongst the delegates present that when assessing the results of the four-colour process printed images produced by the two differing methods both achieved the conditions of the standard. Fundamentally there was very little to choose between the Fogra and the GRACoL7 approach to achieving the specified ISO 12647-2 colour standard”.

BPIF National Technical Adviser Peter Vincent comments “It was very encouraging to see such a large turnout from the industry including colour specialists, industry suppliers, printers and print management companies. The BPIF strongly supports standards and best practice and, above all, consistency of approach within colour management. The feedback from the day was very encouraging”

Printing companies interested in colour management and consistent repeatable colour quality on press may decide to achieve the ISO 12647-2 standard can obtain necessary advice and assistance by emailing [email protected] or calling him on 07720 407 051

Downloads Intergraf Economic News (Paper Prices) - March 2024

Intergraf Economic News (Paper Prices) - March 2024

18 March 2024

Access the latest edition of the Economic Newsletter for the European Printing Industry for data on paper consumption, and pricing data for pulp, paper and recovered paper. Data for packaging papers and board is also available with this edition.

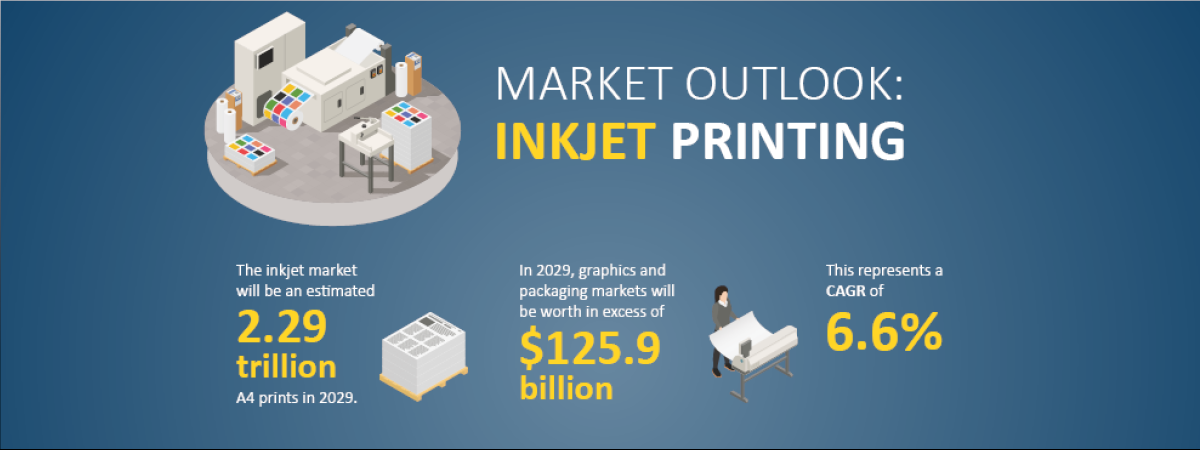

UK to follow global expansion of inkjet printing

UK to follow global expansion of inkjet printing

21 March 2024

The latest expert analysis from Smithers identifies the potential of the latest generation of inkjet systems to improve profitability across the global print market. Read more about the new report The Future of Inkjet Printing to 2029.

The BPIF is the printing industries champion. By becoming a member you join a diverse and influential community. We help you solve business problems, connect you to new customers and suppliers and make your voice heard in government.

Call 01676 526030