15 November 2011

Getting to grips with supply chain management

Trying to tie down a comprehensive and universally accepted definition of ‘supply chain management' reflects the physical management of suppliers in the sense that it is elusive, complicated and often a bit of a minefield.

Many have tried to "bottom this out" but just one quick search on the Internet to gain some insight into supply chain management will return myriad diagrams and theories that only serve to confirm that this is a messy area of business.

Add to this the very real pressure of being squeezed by parties on both sides - suppliers increasing their prices and customers constantly looking for reductions in the price of the product - and the importance of building effective and mutually beneficial relationships with all concerned only becomes more apparent. So what can piggy in the middle (aka the print company) do to push back on the pressures from external suppliers and customers? As with most areas of business, there are tools and techniques. The difficulty is creating a consistent and workable practice that will direct how the business deals with the whole supply chain.

Purchasing as a process

The first area to look at is one that runs through your whole business. Your current working processes should be reviewed and challenged on a continual basis and this area is no different. The best way to have a consistent and effective purchasing strategy is to standardise the process your business uses.

Joint vision/strategy

Work with your suppliers not against them. It comes as no surprise that research done on successful businesses show that they not only have very good win/win alliances with their suppliers but also a similar business culture. Price often is seen as the big decider; however, finding a supplier that complements where you stand in your market segment will often prove to be of greater impact.

Monitoring and joint forecasting

Improved working practices should be a natural consequence of a joint vision. But this should be constantly assessed and analysed. Tightening this relationship will give you the opportunity to look at the trading year and then budget for and pre-empt any possible seasonal trends. Often the biggest reason for vertical acquisitions is to ensure a consistent and reliable supply of materials, with joint forecasting, realistic expectations can be set and implemented.

Benchmarking and Service Level Agreements (SLA's)

"Measure the process not the person" is the phrase most often used when tackling this sensitive issue. It is all very well to plan and discuss the levels required; however, if these are not accurately measured or agreed upon, it may leave your business open to poor service. Break clauses and fines for missing deadlines are becoming more and more prevalent. Obviously these should be the very last resort, but being up front and clear about your expectations will support any dispute resolution.

Question everything

Question why something has been executed a certain way previously and whether it is the best way forward. Are you using best practice? Are there opportunities to automate your ordering system? Does your computer system link with your suppliers? Understandably, your customers likely receive the majority of your time and attention, but why not take time out to look at your suppliers too? Businesses have to strip out waste - just-in-time processes and reduced levels of stock will have an instant impact on the profits you post at the end of your financial year.

Implementation of best practice

Do you have a purchasing manager or a dedicated member of staff who is responsible for your supplier management? Do you need a full time resource, or could this be supported by someone outside the business? However you do it, this area is fundamental to the success of your business.

With external pressures increasing, companies need to look at what areas are under their control. These then need to be identified and exploited to bring the greatest amount of benefit to the company. If you are not making the most of your purchasing and supply chain management you will be less profitable.

Intergraf Economic News (Paper Prices) - March 2024

Intergraf Economic News (Paper Prices) - March 2024

18 March 2024

Access the latest edition of the Economic Newsletter for the European Printing Industry for data on paper consumption, and pricing data for pulp, paper and recovered paper. Data for packaging papers and board is also available with this edition.

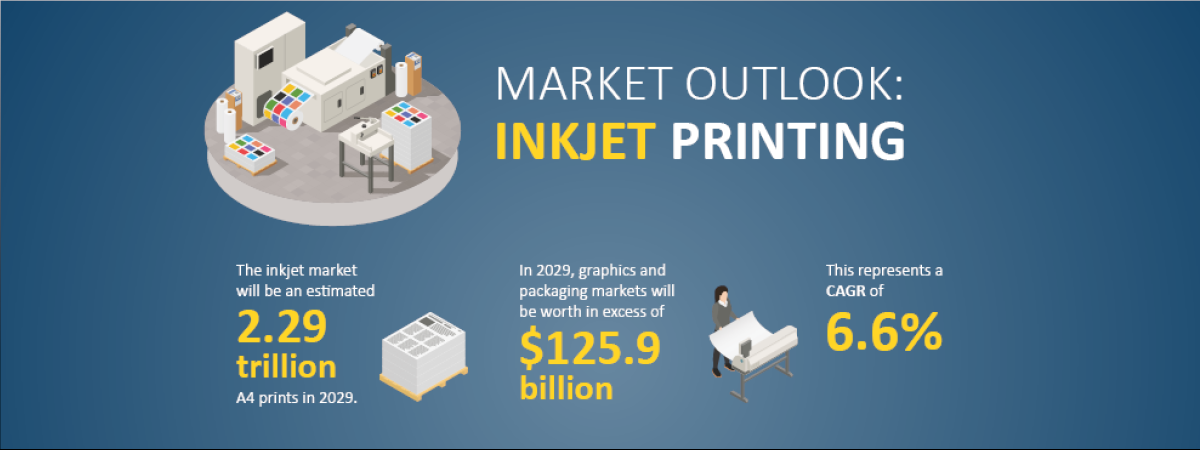

UK to follow global expansion of inkjet printing

UK to follow global expansion of inkjet printing

21 March 2024

The latest expert analysis from Smithers identifies the potential of the latest generation of inkjet systems to improve profitability across the global print market. Read more about the new report The Future of Inkjet Printing to 2029.

The BPIF is the printing industries champion. By becoming a member you join a diverse and influential community. We help you solve business problems, connect you to new customers and suppliers and make your voice heard in government.

Call 01676 526030